Products

Distributor Direct Joint PE Pipe PE pipe Corrugated bend head

Product Introduction

Distributor direct joint

The distributor direct joint is used to connect the distributor and the corrugated round pipe. There are two types of direct joints, one is only for connecting the ABS distributor, the other is only for connecting the sheet metal distributor.

Product Features

• ABS material, light weight, smooth outer surface, easy installation, good stability.

Only for ABS air distributor

Only for sheet metal air distributor

|

Name |

Model |

Scope of application |

|

Distributor Direct Joint |

DN63 |

Distributor with diameter ø 63mm tuyere |

|

DN75 |

Distributor with diameter ø 75mm tuyere |

|

|

DN90 |

Distributor with diameter ø 90mm tuyere |

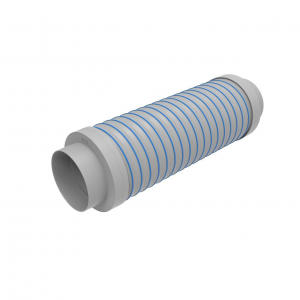

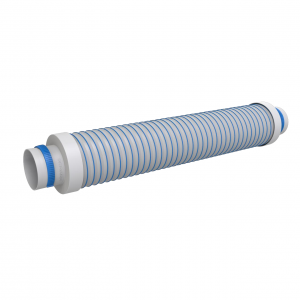

PE pipe direct joint

The PE pipe direct joint is used to connect the PE round pipe and the PE round pipe.It is mainly used for splicing pipes, and must be used in conjunction with the bellows seal ring

, so as to ensure the tightness of the entire system.

|

Name |

Model |

Scope of application |

| Bellows Direct Joint |

DN63 |

Distributor with diameter ø 63mm tuyere |

|

DN75 |

Distributor with diameter ø 75mm tuyere |

|

|

DN90 |

Distributor with diameter ø 90mm tuyere |

|

| bellows seal ring |

DN63 |

Suitable for ø 63 PE pipe |

|

DN75 |

Suitable for ø 75 PE pipe |

|

|

DN90 |

Suitable for ø 90 PE pipe |

|

|

DN110 |

Suitable for ø 110 PE pipe |

|

|

DN160 |

Suitable for ø160 PE pipe |

PE pipe Corrugated bend head

PE pipe 90° bend joint is mainly used for the connection between PE round pipe and PE round pipe Angle. It must be used in connection with the bellows sealing ring to make sure the tightness of the entire system.

|

Name |

Model |

Scope of application |

| Corrugated bend head |

DN75 |

Suitable for ø 75 PE pipe |

|

DN90 |

Suitable for ø 90 PE pipe |

|

|

DN110 |

Suitable for ø 110 PE pipe |

|

|

DN160 |

Suitable for ø 160 PE pipe |

Distributor Usage Diagram

Why Choose Us

Why should choose ABS material?

1、The ABS material has excellent mechanical properties and good impact strength, which can be used at relatively low temperatures. It also has excellent wear resistance, good dimensional stability, and oil resistance.

2、ABS material is not affected by water, inorganic salts, alkali, and various acids, but are soluble in ketones, aldehyde, and chlorinated hydrocarbons.

3、The thermal deformation temperature of ABS material is 93-118 ℃. ABS still exhibits a certain degree of toughness at -40 ℃ and can be used in the temperature range of -40~100 ℃. The transparency of transparent ABS board is very good, and the polishing effect is quite good. It is a material that can replace PC board. Compared with acrylic, its toughness is very good, which can meet the needs of meticulous processing of products.