What is EPP material?

EPP is the abbreviation of expanded polypropylene, a new type of foam plastic. EPP is a polypropylene plastic foam material, which is a high-performance high crystalline polymer/gas composite material. With its unique and superior performance, it has become the fastest growing environmentally friendly new type of compression buffering and insulation material. Meanwhile, EPP is also an environmentally friendly material that can be recycled, naturally degraded, and does not cause white pollution.

What are the characteristics of EPP?

As a new type of foam plastic, EPP has the characteristics of light specific gravity, good elasticity, shock resistance and compression resistance, high deformation recovery rate, good absorption performance, oil resistance, acid resistance, alkali resistance, resistance to various chemical solvents, non-water absorption, insulation, heat resistance (-40~130 ℃), non-toxic and tasteless. It can be 100% recycled and has almost no performance degradation. It is a truly environment-friendly foam plastic. EPP beads can be molded into various shapes of EPP products in the mold of the molding machine.

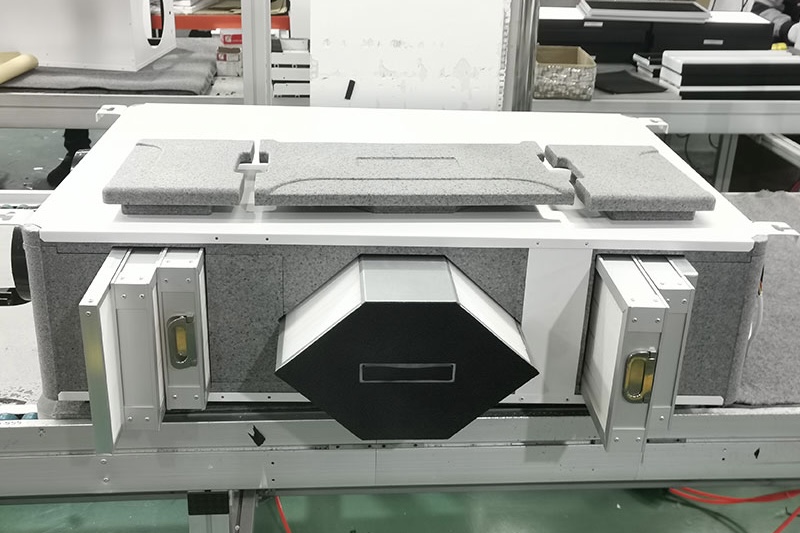

What are the advantages of using EPP in fresh air ventilation systems?

1. Sound insulation and noise reduction: EPP has a good sound insulation effect, which can reduce the noise of the machine. The noise of the fresh air system using EPP material will be relatively lower;

2. Insulation and anti-condensation: EPP has a very good insulation effect, which can effectively prevent condensation or icing inside the machine. In addition, there is no need to add insulation materials inside the machine, which can better utilize the internal space and reduce the volume of the machine;

3. Seismic and compressive resistance: EPP has strong seismic resistance and is particularly durable, which can effectively avoid damage to the motor and other internal components during transportation;

4. Lightweight: EPP is much lighter than the same plastic components. No additional metal frame or plastic frame is required, and since the structure of EPP is manufactured by grinding tools, the positioning of all internal structures is very accurate.

Post time: May-29-2024